Gunter16 Robotics Lab doesn’t look like a sci-fi movie set, yet the place quietly builds the future one circuit board at a time. Walk through the door, and the hum of computers tells you the machines are already dreaming of tomorrow. The room isn’t decked out in blinking neon lights, but a calm confidence fills the air. That same calm fuels every project the space tackles, turning half-finished ideas into working prototypes that get real-world jobs done.

Inside, students wrench on hardware themselves instead of texting theories from the sidelines. Such hands-on practice sticks, and many learners walk away with market-ready skills they can list on a resume within weeks.

Industry veterans show up again and again because the lab spins up prototype support faster than most in-house teams can order coffee. Folks in the field know proof-of-concept work here is never flashy for the cameras, yet almost always useful by Monday morning.

Judges stack projects by their plain old impact rather than by glamour or Twitter buzz. That no-frills fairness keeps everyone honest and even a little kinder than the weekly deadline usually demands.

Funding and gear upgrades trickle in at a steady pace because the lab mates’ money is with the mission instead of headlines. People-first values steer every dollar spent, making sure tomorrow’s engineers feel as valued as tomorrow’s machines.

Key Takeaways

- Gunter16 builds automation tools aimed straight at messy, real-world problems.

- Students tinker hands-on, which helps them walk out with marketable skills instead of just a passing grade.

- Industry partners lean on the lab because prototypes get finished quickly and work the first time out.

- Projects earn praise based on the difference they make, not on how loud the press release was.

- The place grows by stacking small, smart improvements on top of people-first values, not by chasing glittery headlines.

The Humble Start of a Hands-On Lab

Every big adventure kicks off somewhere ordinary, and the Gunter16 launch was about as plain as they come- wire-strewn benches, half-awake espresso cups, and a crew who honestly thought robots could learn a thing or two.

Money was light, and fancy overheads were nowhere in sight, yet the itch to fix everyday headaches with bolted-together gadgets burned bright enough to keep the lights on.

Back in the early 2010s, a few earnest engineers and a couple of university profs slapped the name Gunter16 on the door because they needed a sandbox for playing with robotic arms and learning loops.

News traveled faster than planned: a student wandered in, rattled off an experiment, and walked out with live code by supper; a shipping company dropped a snag on Monday, and blueprints were already sketching themselves by Friday.

While many sister labs filed everything under theoretical, this one kept gears grinding and motors whining, letting proof show up on floor tiles rather than in neatly bound journals, and that runaway habit still fuels the place.

Automation, But Made Practical

Nobody needs to sneak up on the idea of automation anymore. At its heart, the concept is straightforward: let machines slog through the routine so living, breathing humans can tackle work that matters. Every morning in the lab, that headline is what the team circles back to.

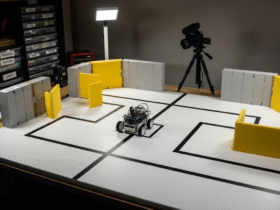

Walk past the bench, and you’ll catch tiny robotic arms learning to grip books that neither sit flat nor line up neatly. Look toward the ceiling, and a boom-mounted camera is figuring out how far away the next shipping crate is.

Nearby, a set of weather-worn sensors is working through the wobble of wind and rain. None of it is idle tinkering; each test answers a day-one headache for packaging houses, drive-in farms, or over-packed freight yards.

The crew at doesn’t6 doesn’t reach for the heavy lingo. They write motion logs, cross-hatch response curves, and count watts like baseball fans tally stats. Power, time, and safety- feel free to call them the cornerstones.

One afternoon, the robot pauses because a mop handle sneaks by. On another, it cradles a porcelain plate as if the air itself were brittle. Daily drills like those pile on top of one another until the combination looks effortless after deployment. In real life, that repeat run is what turns nervous prototypes into equipment everyone trusts.

Industry Trust Is Earned, Not Bought

Companies that reach out to Gunter16 usually expect a slick sales deck, maybe even a World-Class Partner plaque. Instead, they sit down on a plain bench, sip weak coffee, and talk shop with engineers who listen. That kind of no-frills honesty is almost extinct in consulting circles.

Clients keep coming back because the crew at Gunter16 trades empty buzzwords for dirty hands. They draft, they test, and sometimes they fail right there in front of you. A reputation like that turns word-of-mouth into a waiting list.

Prototype builders love the lab because it never pretends to be perfect. Sensors drift, drones corkscrew in the wind, and every glitch is logged, not ignored. Startups say they shave months off deadlines the moment those problems get daylight.

Inside those concrete walls, time and money don’t disappear into the usual smoke and mirrors. Partners know the team will zero in, swap guesswork for data, and then follow up with real fixes. For founders racing the clock, that kind of predictability feels almost like luck.

Students Don’t Just Learn, They Build

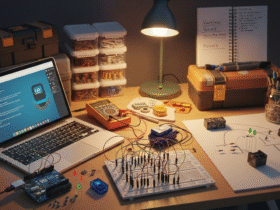

Walk through the lab with a student badge, and nobody hands you a packet of safety drills to memorize.

When someone says think like a builder, they mean hands covered in grease and a mind racing toward the next fix.

You won’t hear a principal rattling off PowerPoint slides inside this lab because screens and long lectures get swapped for clanking soldering irons and blinking motion sensors every single day. A messy, living workshop claims all the floor space instead of neat rows, and that chaos turns out to be a great teacher.

A student who dreams up a wrist-mounted gripper that can cradle a wine glass starts by chucking fuzzy sketches onto cheap printer paper. The circles and arrows soon land next to pin headers, magnets, and any off-cut wire the trash can cough up.

Wires bend, circuits hiccup, code crashes, and that four-step routine signs the same invoice over and over until a smooth lift finally shows its face.

Nothing in a textbook tells the arm to relax or jerk back; only the machine, stubbornly refusing to lie, exposes where trouble lives. People call this project-first learning, and everyone inside the walls calls it Tuesday.

Most university grads head into the world heavy with slide-rule theories that someone else perfected decades ago.

The student who sticks a wrench in this workshop gut check walks out dragging a suitcase stuffed with built-ahead-of-time proof instead of a borrowed promise. Two-year-old prototypes gather dust on their shelves, they’re still rusting somewhere under the workbench, but each one quietly shouts, I did it.

The Projects That Made People Stop and Look

doesn’t6 doesn’t pump out over-the-top press releases. Now and then, though, something slips through the cracks, and people pay attention.

A couple of years back, a mixed crew of students and lab techs knocked together a lightweight robot designed to hang around a warehouse floor. The little one wasn’t someone’s job; it just wanted to tag along, carry a few boxes on people’s backs.

The bot learns to follow by watching how a person walks. It keeps a comfy gap, listens to shouted orders, and freezes if the worker takes a breath

. That simple trick got noticed because it tackled a headache that most managers care about. In a warehouse where every penny counts, this sidekick can stretch a shift and stop employees from quitting.

Another head-turner came from the fields rather than the loading docks. A bench of engineers built a grab-and-scan sorting station that snaps pictures of crops and doles them out by size.

Handy for co-cant-can’t cough up for pricier gear, the gadget shaves hours off harvest day. None of these builds are lined up for trophies; they show up, do their thing, and keep earning their keep long after the buzz fades.

How the Lab Keeps Getting Better

You might ask yourself: How does Gunter16 keep adding features without falling apart? The team answers by staring at its reflection. Every few months, they sit down, slice the data, and decide what stays and what goes. No glossy headlines, just hard numbers.

They also insist on reading the wider world. Fresh papers and conference talks pile up on the desks, and the crew flips through them every night. If an idea looks like it can untwist an old problem, they drag it into the code. Otherwise, it gets a polite no, thanks.

That push-and-pull between new inspiration and old reliability is why the lab stays in front. Chasing buzz may be fun, but keeping things practical is what moves the needle.

Solving Real Problems That Affect Real People

Gunter16’s soul isnát silicon; it is flesh and blood, the people who breathe easier once the machines get to work.

One recent upgrade lets a cramped shoe factory shut in minutes, freeing up hands that have been idle for decades. Another project turns voice into motion, so a gardener with shaky wrists can watch a robot water flowers on command. Real tweaks for real lives, none of the sci-fi fantasy.

Tech articles love gadgets, but they skip over the quiet heroes in the lab. A workshop earns its stripes not because of flashy prototypes but because someone gets a new chance.

Gunter16 never forgets that lesson. Their whiteboards are crowded with one blunt question: Who does this help? Answering it first keeps them from wandering off in search of the next cool toy that nobody wants.

The crew ignores wild hype cycles, too. They dont pretend automation fixes everything with a snap. It behaves like any tool in an expert’s hands; it’s downright ruthless; in careless hands, it barely lifts a finger. Instead of spells, the engineers trade in routine, stubborn grit.

Looking Ahead Without Losing Their Way

It would be tempting for Gunter16 to chase the glamour, plant a giant logo on every flight log, reel in a cash round, and overhaul the whole setup. So far, the crew has shrugged off that shine, choosing instead to stay a bit grime-covered and wide-eyed on the shop floor.

In practice, that looks like scaffolding fresh modules for drone test beds, sneaking low-watt gadgets onto a new lineup of ground bots, and yanking in undergrad talent straight from mid-state colleges. Those projects rarely make a trade rag cover, yet they quietly tilt the scales in favor of wider access and legitimate utility.

That everyday pride check is why Gunter16 still matters, even against flashier names in the space. The outfit nets headlines less for wild stunts and more for asking whether the next wave of automation is usable. Spoiler: it usually is.

My Opinion | Why Gunter16 Deserves the Spotlight

Any reader who thinks tech should help humans, not haze them, ought to bookmark Gunter16. This place tells flying machines to ferry packages, not to mimic Hollywood villains.

A fresh-faced intern can poke, prod, and occasionally blow up a circuit before lunchtime- most lessons stick after that. Industry sponsors keep drifting back because they leave with prototype answers, not PowerPoint questions.

None of that glints like billion-dollar hype, yet Gunter16 keeps earning its quiet encore in the wider robotics chorus. Sometimes, steady work gets the loudest applause when nobody else is watching.

Good leaders in automation never boast about a glitzy gadget. Instead, they spot a problem, hammer out a real fix, and show everyone else how to repeat the win. That simple, hands-on approach is what counts.

Leave a Reply

View Comments