Technology never seems to catch a break or put its feet up. Sure, 2025 zipped by like the previous busy years, but this one left a mark if you were paying any decent attention to Anyware Robotics.

A buddy of mine who roams factory floors and checks safety gear first dropped their name. He talked about a small, humming drone that sniffs out a chemical leak way before anyone tasting metal in the air notices a thing. The image stuck in my head.

From that point, I chased Anything with their logo. Phone calls, LinkedIn messages, company slides, even the half-hidden forum threads. Before long, it hit me: whatever this crew was baking was more than smoke and mirrors; it was proper machinery.

Oddly enough, they never launched with flashing lights or loud stage demos. Most of their kit rolled out in quiet beta, fixed messes that nobody else bothered to touch. That no-nonsense vibe is why most insiders started whispering, then talking, and I guess now blogging about them.

So what shook 2025? Let me lay it out, because the answer will probably echo through classrooms, warehouses, and maybe even your living room for years.

Key Takeaways

- Anyware Robotics kept its eye on sweaty, brick-and-mortar problems, not next month’s wider buzzword craze.

- A wearable exosuit popped onto nursing floors and elder-care homes, easing the grind with motion that feels almost normal.

- AI-stuffed flying eyes cruised building rafters and scaffolds, yelling hazard alerts before a human even lifts their head.

- Picture a warehouse where little robots glide around on their own, quietly picking up boxes and learning from the humans they work beside, not replacing them.

- Somewhere else, kids are building motors out of spare parts and calling it Saturday fun, and that simple craft hour is sneaking STEM lessons into their weekend playtime.

A Humble Start with Big Intentions

Anyware Robotics never rented a marble lobby or plastered startup catchphrases in neon lights.

The shop is desks shoved together, late coffee, and engineers who lean on one another until the part finally works.

Early prototypes rolled out with school stickers, not quarterly numbers, because the team wanted classrooms and community shops to see something useful on Monday.

Price tags stayed modest; a tough sell if the gear breaks after shipment, so busted prototypes ended up in the scrap bin before the factory would touch them.

Progress meant patience -rovers that took forever to master a single route got rebuilt, not shipped and ignored.

By late 2023, fresh upgrades flooded inboxes at educators, factory managers, and hospital leads, nearly at the same hour.

Plenty of firms boast of burning cash for glitzy launches. Anywhere prefers quiet listening, real-world tests, and honest follow-up phone calls long after the press release. That attitude showed up in every new feature this fall.

What Drove Their 2025 Breakthroughs

The calendar flipped before anybody was ready. By early 2025, hospital hallways were tighter, factory crews looked worn-out, and crumbling bridges were rattling under extra load.Anywheree didn’t waste energy tracking shiny new trends; the crew zeroed in on real headaches, and that instinct fired up their most eye-opening fixes.

Forget the flashy demo of a robot break-dancing on a trade-show floor. Engineers slipped into over-stuffed ERs, hung around night-shift porters, and sat with teachers pinching pennies for a basic science kit. Coffee-stained notes from those site visits blossomed into hardware and apps that matter, not trophies.

That boots-on-the-ground spirit steered each gizmo off the drawing board. Every piece-caster, code line, chassis was built to slice away a specific ache, whether financial squeeze, back strain, or paperwork logjam. No bells, no whistles, just plain work.

The Exosuit That Gave Caregivers Their Strength Back

A few months ago, I talked to a nurse in her late forties. She had lifted patients long enough that bending down felt like cracking her spine. The idea of an early retirement hung over her like a cloud.

On a lar,k she slipped into the newest Anyware Exosuit. At first, it looked like nothing special- just a high-tech backpack with straps across the legs and waist. Once the power kicked in, the suit hugged her core and legs like a quiet hug from behind.

She said the extra strength arrived exactly when she needed it. There were no awkward buttons to press and no fresh calibrations to juggle every shift. The supply watched, learned, and moved with her.

Inside the fabric, soft pneumatic actuators worked with a tiny AI engine that guessed her next move. One quick training session locked the memory in place. After that, every lift and bend felt smoother, almost invisible.

Because the nurse responded without thought, she would spend more time talking to her patients instead of bracing for the next transfer. The added stability also made patients relax, a good sign when you are 150 pounds lighter than the person you are lifting. Pain dropped, confidence soared, and retirement plans were put on hold.

A Drone That Sees Problems Before People Do

Picture yourself walking a pipeline that stretches across empty fields. The sun is out, the steel looks solid, and the air is calm. You move along, unaware that something deep inside the joint is about to fail.

Enter an Anyware drone built for these lonely stretches. It glides in, pauses without a sound, and sends a digital warning. The heat profile is off, and microscopic vibrations are rattling the metal.

This model, slated for 2025, weighs next to nothing and runs on layered deep-learning brains. More than a glorified UAV, it rewrites its flight path based on thermal, acoustic, and even chemical clues. Inspectors have field-tested it on offshore rigs, urban tunnels after quakes, and thousand-mile pipelines, catching hidden fractures long before they open to the sky.

The little drone can buzz into the narrowest shafts and draw a fresh map while you wait. An onboard AI sifts through the chatter, pinging you only when its sensors spot something that really can’t be ignored. A maintenance pro I interviewed said it shaved off three whole hours of walking the site every day and, just as crucial, probably dodged two scary failures this year.

So yes, the gadget cuts drudge work, but its bigger job is cutting danger. In factories or oil fields where one slip can cost a life or bleed out millions, that kind of tech isn’t just cool; it’s a real game-changer.

A Warehouse Robot That Watches, Learns, and Helps

Walk into a modern shipping warehouse and you can almost hear the clock ticking. People hustle, drop a box now and then, then curse under their breath. That steady heat of pressure never lets up. Nobody anywhere wanted to punch that ticket. They figured true relief meant a partner, not a replacement.

So they cooked up a bot with its own set of eyes and a nose for detail. First thing it does is stand still and watch the floor crew go about their day. How does Mark cradle the glassware? Which aisle does Janet dodge when the crowd thickens? Even the tiny habit of double-checking a label gets logged, frame by frame. After soaking all that in, the machine jumps in as a second set of hands instead of a clumsy copycat.

One handler joked it was like training a sharp intern who paid attention. The bot stumbled through the first shift, no question, but by Friday, it was nearly keeping pace and trimming mistakes. So, it was hauling cartons back and forth and sorting mail bins the way the team already liked. That small victory gave everyone a breather.

This robot isn’t just another shiny gadget. Its main trick is feeling something like empathy. Engineers built it to ease human fatigue, not to push people out of the job site, and that twist on who technology is for is what keeps folks buzzing about it.

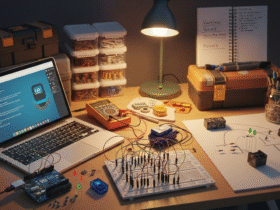

A Robotics Kit That Doesn’t Intimidate Kids

During a quick visit to an Oregon classroom, I stumbled upon Anyware’s latest educational kit. Fifth graders were sprawled across the floor, not glued to screens or waiting for a lecture, and their energy filled the room. Wheels slid into place, blocks of code fired off, and the little machines ricocheted off walls like excited puppies learning boundaries.

Nobody flinched when a robot toppled over. Laughter rolled through the air, they fixed the glitch, and high-fives landed for every tiny win. The kit draws its power from that simple, pure delight in testing limits instead of from high-priced gear or an engineering degree. Curiosity is the only gatekeeper.

Color-coded ports snap together with a satisfying click, and the assembly guide is almost all pictures. Coding feels more like dragging stories into place than wrestling with syntax. Even better, every bot arrives with a software-generated quirk-a pretend laugh, a goofy light pattern-and the kids name them, grouse at them, and cheer them on. That connection turns circuitry into a working partner, and in the meantime, math and logic lessons slip in under the radar.

One little robotics kit did more than run through circuits and code; it flung open an actual door to new learning. In classrooms that squeeze every dime and every minute, that moment can tip the scale from yawn to wow.

Why Their Work Feels So Different

The usual press buzz booms, then disappears, and the teachers are still standing in the same cramped room. Anyware Robotics skips the fireworks. They care more about the person than the PowerPoint slide. That switch of focus, toward plain people instead of celebrities, shows up the second the machine hits the floor.

They aren’t chasing money or hashtags, just gnarly problems sitting right in front of them. They load gear into beat-up vans, wander to windy ports or dusty factories, and spend real hours learning what breaks. Feedback lines stay open, blame stays silent, and any fix lands the same day if it can be helped. Bottom line: the gadget isn’t a genius unless it quiets one tiny hassle from a human life.

I’ve logged too many late nights watching glam prototypes glow behind glass. Anyware hands you something that needs zero explanation and then makes you ask why the last ten toys didn’t do the same. It just runs. Once the dust clears, you wonder how you ever did without it.

Where ThThey’reoing Next

The crew won’t park the idea in the garage. Right now, they’re beefing up an exosuit for warehouse grinds, swapping rigid joints for softer, bendable ones and boosting the frame so it can hoist heavier crates without groaning. Meanwhile, the school kits are getting a fresh brain, with color-spotting sensors that let kids code their tiny robots to light up in blue, red, or any shade in between.

About that drone: engineers are yanking cables and rewriting lines of code to send it screaming into disaster wreckage, places where every ticking minute turns precious. One flight like that, they say, could turn loss into rescue in the snap of a finger.

Over coffee, the team casually mentions sharing bits of their code with overseas partners and letting smaller startups tinker with the same hardware. Ask them what drives the hustl,e and, almost sheepishly, they admit to wanting to fix problems that breathing peoply feel.

Missions like that never wear out; they burn brighter.

My Opinion | The Quiet Revolution of 2025

Please scroll through the headlines of the past twelve months, and much of it sounds loud yet forgettable, another loop of flashy demos that fade by summer. Yet somewhere under the noise, Anyware Robotics quietly stitched together tools that count.

A nurse slips out of her scrubs without back pain for the first time in years. One small drone scans a crumbling highway and sends a ping, spare minutes arriving just in time. Somewhere, a teenager, thumb-deep in code, decides a future prototype no longer feels like daydreaming. A delivery driver slides on an augmented visor, arms still free, and grins because the machine finally keeps pace.

Think of what follows as a heads-up, not a bedtime tale. Real breakthroughs dont hide behind a wall of gadgets; they stand out in plain sight. In 2025, Anyware showed the world that a friendly robot can be both simple and stunning.

A robot that pays attention, gets the point, and pitches in is no longer a pipe dream. That vision landed in 2025, thanks to a crew that refused to settle for Anything less.

Leave a Reply

View Comments