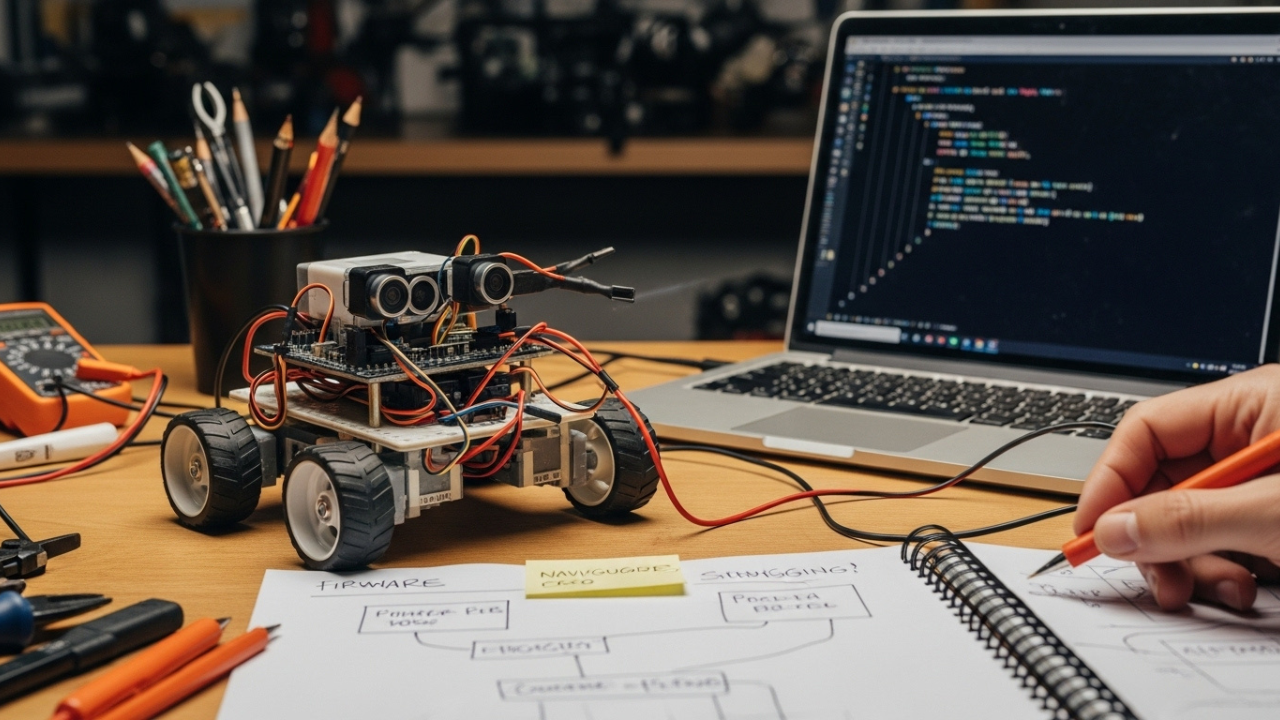

Let me guess — your robot moves beautifully in one test, then spins in circles the next. Sometimes it reacts fast. Sometimes it just… doesn’t. If you’re stuck trying to figure out why your robot can’t follow a simple path without losing its mind, you’re in the right place.

Hi builder — this guide was written for someone just like you.

I’ve spent countless hours working with DIY robots, especially mobile bots meant to navigate spaces, follow lines, or avoid obstacles. The thing is, once the wiring looks fine and your code seems clean, there’s one layer of trouble most people forget to check — the firmware. It’s not glamorous. It’s not often visible. But if your robot is acting unpredictably, chances are the answer is buried somewhere in that invisible layer.

It is time to peel it off, we together, carefully and explicitly, so that we can fix what is really going wrong.

Key Takeaways

-

Firmware bugs often hide behind symptoms that seem like power, sensor, or motor issues.

-

Inconsistent loop timing is one of the most common causes of bad navigation.

-

Sensor conflicts on shared buses like I2C can silently break behavior without error messages.

-

Reflashing firmware with a clean base version helps clear hidden memory issues.

-

Testing navigation with stripped-down code reveals firmware flaws faster than full trials.

Why Firmware Errors Matter (Even If You Didn’t Write the Firmware)

You might assume firmware errors only happen to professionals writing code for commercial robots. But here’s the truth: most DIY robotic kits, boards, and modules come pre-loaded with firmware or depend on libraries that include firmware-level instructions.

That means every Arduino sketch you upload? Every PID controller you try? Every navigation library you call? You’re interacting with firmware — whether you realize it or not.

Firmware is the middleman between your robot’s brain and its body. It takes your high-level commands (like “turn left when near a wall”) and turns them into low-level instructions like setting PWM values, reading sensor registers, or storing coordinates in EEPROM.

So when your robot goes rogue, even if your visible code is solid, the firmware can be where things silently break.

Recognizing the Signs: What Firmware Errors Look Like

Before we dive into tests and fixes, you need to know what you’re looking for. Firmware bugs don’t always crash the robot. More often, they create inconsistent behavior that only shows up when your bot is in motion.

Here are a few red flags I’ve seen repeatedly in navigation projects:

-

The robot starts correctly, then slowly drifts off-course

-

Motors respond with a delay, even though input looks clean

-

The robot avoids obstacles — but only sometimes

-

It forgets its position when switching from one mode to another

-

It behaves differently after a reboot, even when nothing changed

Sounds familiar? That inconsistency — where it works some of the time — is one of the clearest signs that firmware might be the problem.

When My Robot Thought It Was Facing North (All the Time)

Let me tell you a quick story.

I built a simple 4-wheeled robot with a compass sensor to help it rotate toward cardinal directions. I calibrated the sensor, fed its values into a heading loop, and added a “navigate north” mode. Everything worked… until it didn’t.

Every few minutes, the bot would randomly think it had already reached North — even when facing the wrong direction. I checked my math. I reset the sensor. Still nothing.

Turns out the firmware in the compass library had a memory issue. It wasn’t properly refreshing sensor readings unless the bot was standing perfectly still for 300ms. That tiny detail caused hours of misdirection.

I replaced the sensor library with one that forced manual refreshes. Problem solved instantly.

This is what firmware bugs feel like. You don’t see them. But you live through the chaos they cause.

Getting a Grip: Isolating Firmware Errors from Hardware or Logic Faults

To solve firmware problems, you have to narrow the field. Many builders waste time adjusting the wrong part of the system because they assume it’s always a sensor or battery issue.

Let’s break this down.

If your robot glitches at random times, across different environments, and especially after a reboot or update — firmware is a strong suspect.

If the issue only appears during motion, especially complex turning or speed shifts, check your firmware’s motion routines.

If the robot’s behavior changes after updates, or if you’ve recently added new sensor libraries or flashed new code, firmware conflicts are a likely cause.

Here’s a quick strategy that works wonders:

-

Strip your robot’s code down to only motor commands — no sensors, no conditions.

-

Manually command it to move forward, backward, turn left/right.

-

Observe closely. Assuming that you still experience glitches, you have eliminated the chance that it was a problem with logic and it has been reduced to either hardware or firmware.

At that point you will be able to proceed without fear.

Use Serial Output Like a Detective Uses Clues

The best tool in your hands right now? Serial.print().

Seriously. Your serial monitor gives you a real-time look at what your firmware and sensors are doing — even when the robot acts fine on the surface.

Start logging the following:

-

Raw sensor values (before any smoothing)

-

PID calculation steps

-

Navigation targets vs. actual positions

-

Motor speed commands sent vs. actual motor output

Even a simple line like:

…can tell you whether your firmware is actually receiving correct data or just pretending to.

You’ll be amazed how many times the firmware thinks it’s doing the right thing — but isn’t.

Firmware and Memory: Invisible But Deadly

Here’s something most builders overlook completely: memory management inside firmware.

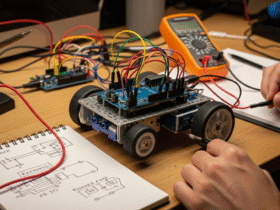

. DIY bots are commonly based on small microcontrollers – Arduinos, ESP32s, STM32s, etc. that have very limited memory (the amount of RAM and flash) available. Values can be silently corrupted when your firmware stores excess data, or writes to the same EEPROM cells a number of times.

That’s how you end up with a bot that:

-

Forgets sensor calibration after restart

-

Saves old position data and loads it again

-

Crashes during navigation after a few loops

Watch for signs of memory overflow:

-

Delayed motor response

-

Random freezes

-

Incomplete sensor data

One way to fight this? Use memory check functions. Some platforms let you monitor free RAM. Others allow you to see how EEPROM is being used. Keep logs small and loop timing light.

The Subtle Bugs That Break Everything

Here is what you can imagine: your robot switches on, surveys its environment and starts to move according to a predetermined route. Everything looks smooth — for about ten seconds. Then it overcorrects. Then it hesitates. Suddenly, it turns the wrong way and stops in front of nothing.

These are the kinds of bugs that live inside firmware-level routines. They’re subtle. They usually don’t crash your system. But they make your robot act strangely because a tiny value was off, or a loop didn’t complete in time, or a sensor didn’t return a real reading.

You might have seen this with PID controllers. You enter values, tweak gains, and expect your bot to adjust steering gradually — but instead it makes huge corrections or none at all. In many cases, the issue isn’t your logic — it’s that the firmware reads and writes values in a timing sequence that’s out of sync with the rest of your code.

So just to be on the safe side before you go starting to tune anything, you should ensure the firmware is not getting the timing wrong. Such a delay in reading data sent out by the sensor (even by something as short as 50 milliseconds) can make your robot believe that it is not on track, whereas it really is.

Timing Matters More Than You Think

Every moving robot relies on precise timing to keep control loops stable. Your firmware doesn’t just push commands out — it cycles through loops that check sensor data, compute errors, and apply corrections.

If those loops don’t run at a reliable rate, navigation breaks.

One of the most common firmware bugs I’ve seen in DIY robots is an unstable loop frequency. This means that your navigation logic is running too fast or too slow — or even worse, inconsistently depending on what else is happening.

Let’s say your navigation function is inside a loop() block that also handles Bluetooth input and LED effects. You believe you update your heading at every 100ms but in actual sense only when LEDs animation is complete to update your heading at every 300ms.

The fix? Decouple navigation logic with anything cosmetic. Use timing control, state machines, or interrupts to make sure the firmware doesn’t get held up waiting for other tasks to finish.

The Silent Sensor Conflicts

Sensor issues are often blamed on faulty hardware, but they can also be caused by firmware-level conflicts — especially if you’re using multiple devices that share a bus like I2C or SPI.

Take this example: you connect an IMU and a rangefinder to the same I2C line. Both use default addresses. The moment you add both to the robot, you start seeing motion glitches. Your navigation becomes unreliable. The rangefinder reads once, then stops. Your heading is frozen.

What’s happening?

The firmware in the sensor libraries doesn’t handle shared addresses well. Or maybe both devices try to communicate at the same time. Either way, data collisions happen — and your robot loses trust in its sensors.

Solutions here aren’t always elegant, but they work. Change addresses where possible. Stagger sensor reads to avoid overlap. And if you’re using third-party libraries, dig into the code to check how they manage bus control.

Firmware bugs in sensor timing are sneaky because they don’t cause errors — they just cause bad data.

Firmware Error Table: What’s Really Going Wrong?

Let’s simplify this into one table — useful for both diagnosis and debugging. This table maps common robot behaviors to possible firmware issues and suggested checks.

| Robot Behavior | Possible Firmware Issue | Suggested Debug Focus |

|---|---|---|

| Overcorrects or jerks during turns | Loop timing too fast/slow | Add consistent delay or timing control |

| Navigation path randomly fails | Sensor data not refreshed or overwritten | Verify sensor read frequency and sequence |

| Motors hesitate or lag | PWM update too infrequent | Inspect motor update timing in firmware |

| Bot forgets settings after restart | EEPROM write/read bug | Re-test EEPROM logic or use fresh values |

| Random reboots during navigation | Memory overflow or watchdog reset | Monitor RAM usage and loop execution times |

This isn’t a complete list — but these five issues represent over 80% of firmware-related bugs in navigation.

And here’s the most important part: each one feels like a different problem (power, motor, logic), but the root cause lies inside how the firmware is written or how it’s managing its tasks.

Firmware Flashes and the Importance of a Clean Slate

If you’ve tried fixing bugs by editing code over and over, uploading new sketches, and watching for changes — but your robot still acts the same — then it might be time for a clean firmware flash.

Sometimes, the firmware stored on the microcontroller gets partially overwritten or corrupted. This can cause old logic to linger. It can also create memory artifacts that mess with loops, sensor readings, or pin behavior.

The solution? Wipe the board and reflash clean firmware. Start with a minimal program — just enough to control motors and blink a status LED. Test that first. Then, layer in your navigation code, slowly, and test at each step.

This might sound tedious, but it’s the most reliable way to clean out bugs caused by firmware residue. Many seasoned builders keep a “starter firmware” file handy just for this reason — it brings their robot back to a neutral state quickly.

Real Case: A Bot That Couldn’t Stay on the Line

Let me tell you about a bot I helped debug at a community workshop.

It was a line follower — simple design, IR sensors on the bottom, two DC motors, classic black tape on a white floor setup. The code looked fine. The bot followed the line at first… then randomly drifted off. No pattern. No repeatability.

We checked sensors. Clean. Motors? Working. Power? Stable.

The issue? The firmware was sampling sensor data using a non-blocking timer, but the motor control logic depended on real-time sensor values. That tiny timing mismatch caused the bot to always act slightly late — just enough to drift off course at curves.

We synced the loop, added a stable read-update cycle for the sensors, and introduced smoothing for noisy readings. The bot ran cleanly for the rest of the day.

Building a Smarter Test Plan

Once you’ve fixed the core firmware problems, your job isn’t done. You need a test plan — not just for now, but for future projects too.

Good robot builders don’t just build bots. They build repeatable testing systems that reveal firmware issues before the robot hits the floor.

Here’s what works well:

-

Run simulated input tests before physical trials.

-

Track expected sensor behavior for each movement.

-

Log sensor and motion output with timestamps.

-

Watch for spikes, freezes, or dead values in your logs.

You don’t need expensive tools. Even a simple CSV export or a notepad with a stopwatch helps.

The goal is simple: catch firmware errors in a controlled setting, not when your robot is halfway under the couch.

Final Thoughts

You’ve made it through the full path — from spotting strange movement glitches to digging deep into firmware routines that most hobbyists never think to check.

This article wasn’t just about theory. Every section is rooted in real problems seen in real robots — the kind built in homes, classrooms, labs, and garages. The kind you care about.

Firmware bugs are invisible, but they’re not impossible. With the right mindset, you don’t just fix the problem. You understand it. You prevent it next time. You become the kind of builder who can take a blinking, twitchy prototype and turn it into a smart, reliable machine.

And trust me — once you get there, it feels really good.

Leave a Reply

View Comments