If you’ve seen a robot glide without jerking, you’ve probably wondered what invisible trick is at work. More often than not, that trick is a brushless motor hiding behind a cover plate you can’t even spot.

No buzzing hum gives it away; no clouds of burnt dust signal its presence. Still, the motor quietly hands the machine its balance, stamina, and featherlight control.

After poring over kit projects in garages and chatting with engineers running factory bots, another truth pops up: the brushless design is the real unsung star of modern robotics. Let’s step slowly through the how and why, clearing out the jargon and shortcutting the hype. The goal is to leave you with a simple sense of why this gadget powers everything from student demos to assembly-line titans.

Motor’s core idea is slick electronics replacing dangling brushes that grind materials away. That swap stretches lifespan, nips maintenance, and silences the rattle normally heard inside rotating gear heads. So the machines move cleaner and respond faster.

Because sensors nest right in the circuit stack, feedback loops shrink to milliseconds.

Key Takeaways

- Brushless motors trade physical friction for electronic control, which means less wear and smoother action.

- Immediate feedback lets robotics writers program tighter, more responsive movements.

- Aside from silent operation, the design keeps heat drains small, so transit trucks and hobby bots alike run cooler.

- Tight integration with onboard electronics sets the stage for machines that think even faster than we do.

The Shift from Brushed to Brushless

Not long ago, nearly every small robot still spun on a brushed motor. Hook up the wires, feel the vibration, and call it a day. That simplicity had a flip side: little metal brushes scraped against a rotating commutator.

Over weeks or months, that constant rub wore parts thin, black dust settled in corners, and heat warnings flashed. For one-off experiments, it was no biggie, but production runs demanded something tougher.

Enter the brushless design. A web of magnets and circuit-board brains took the place of those clunky brushes. Fewer bits grinding together meant lower friction, less mess, and a shelf life that could stretch into years.

Picture an office fan you have forgotten about for twelve straight months, yet it hums on cue when you finally flip the switch. That level of reliability surprised engineers and hobbyists alike when brushless gear hit the scene.

With cool, steady power like that, robots suddenly mastered smoother moves, drank less battery juice, and shrugged off jobs that once sent machines to the shop for repairs. The move to brushless modification didn’t just tweak the tech- it redefined what small machines could dare to attempt.

The shift to brushless motors crept in slowly; you won’t budge now. Why? Because it cleared up headaches that had haunted engineers for years. A robot’s victory lap can hinge on a single gear turning just the right way, so picking the right motor feels huge.

These days, that gut feeling almost always nudges builders toward brushless. The tech is quieter, cheaper in the long haul, and flat-out refuses to wear out the way its brushed cousins do. That reliable edge is nearly impossible to ignore.

Understanding the Magic Inside the Motor

Ever stop to wonder why so many gadgets now hum quietly instead of rasping? The answer usually sits where you can’t see it- a brushless motor. Break the idea down with everyday logic instead of jargon, and the mystery shrinks.

Every motor, old-school or modern, craves two things: a magnetic push and a part that spins. A brushed motor provides that push by dragging current through copper brushes that scrape across the rotor. Heat and dust collect, the brushes wear, and performance drops.

A brushless design wipes that friction clean. Engineers swap copper contact points for a driver circuit that flips the magnetic field on and off in split seconds. You end up with a rotor that turns beneath coils wound onto a fixed stator or, in some cases, the other way around.

Because nothing touches, the rotation stays smooth, and the components cool. Picture giving a playground swing a timed shove from five feet away; your hand never brushes the rope. Electronics nearby trackswitrack swinging ‘snd throttle the push just right.

Once you see that timing circuit at work, the design feels obvious rather than magical. Smooth operation replaces clunky wear, letting batteries stretch their dollars a little farther.

Why Robots Choose Brushless by Default Now

Robots don´t like surprises, and neither do the people who run them. ‘That´s why engineers keep choosing brushless motors. They keep going without overheating, quit sparking, and obey instructions almost on instinct. Performance like that is priceless on a factory floor or inside a hospital room.

Look at the arms that weld car frames. They stop on a dime, hold a part steady, and never creep when the boss isn´t watching.

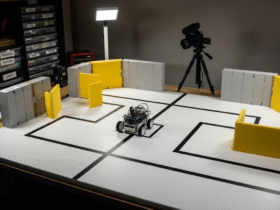

Drones, which need to orbit a playground as quietly as a snowflake, are built on the same silent design. Even the tiny coding-project bots that zoom around classrooms lately sneak a brushless in-motor under the hood. Once you feel that quick, smooth response, you wonder how you lived without it.

Another big reason is control. Engineers can dial in acceleration, speed, and dead-stop time as if they´re an organ.

That level of precision saves surgical tools from jerking when lives are on the line and keeps fragile parts from shattering during a stack-up. Brushed motors, with their built-in guesswork and wear, can´t keep up. For robotics, where every tick of the motor shaft can cost money or safety, the repeatability of brushless design is worth its weight in gold.

A Robot’s Story That Shows It All

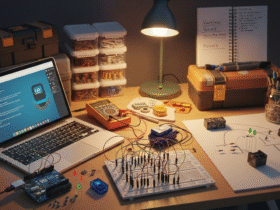

Not long ago, I wandered into a university robotics lab and spotted something cool. A small delivery robot was taking shape, built to zip down narrow hallways and haul fresh supplies. The design brief read like a checklist: smart stops, steady holds on sloped floors, and speed that matched whatever load it carried.

The prototype ran on off-the-shelf brushed motors, and, honestly, it looked fine on the test stand. When nobody was watching, though, it would jolt at every stop and slide sideways on the slightest incline. After an afternoon of practice, the little robot would stink of burnt copper and need half a dozen tweaks to crawl home.

Without skipping a beat, the crew yanked out the brushed setup and slipped in compact brushless motors paired with a custom controller board. Suddenly, the start-and-stop behavior was buttery smooth, almost as if the robot was thinking ahead. Steep ramps no longer scared it, the heat stayed in check, and the whole thing just felt alive under their fingers.

That transformation wasn’t sheer luck or a fluke of the moment. It came from choosing gear that responded faster, chewed through less power, and asked for very little care once it was tuned. With the motors sorted, the team could finally spend their evenings perfecting navigation code instead of nursing dead motors back to life.

Not Just Pits out Communication Too

A lot of folks think brushless motors are just wires and magnets, but they carry a surprising brain-stem level of cleverness. Many slip a tiny controller right inside, or they buddy up with one nearby so the coil learns the perfect moment to buzz.

That instant chatter forms a closed loop, and without it, none of the day-to-day machines would move as they do. The shaft spins, yes, but each twist also whispers how hard the unit is working and whether it is close to throwing a fit.

Now imagine a robot arm that plucks a mug from a table and immediately senses the ceramic’s weight. Instead of burning out, the joint eases up and grips tighter. A delivery drone does something similar: it feels a gust and tweaks its blades before wobble becomes dive.

Those examples are visible on factory floors this week; they are not scenes from a 2060 blockbuster. Because the rotor shares brain data at warp speed, it stops being mere muscle and turns into a real-time decision-making ally. In short, that marriage of motion and thought is the secret sauce, giving modern robotics its wow factor.

When Brushless Motors Might Not Be the Right Fit

Not every build needs a fancy brushless motor, and I can admit that. Picture a weekend hobby project where cash is light- you wire up a simple brushed motor and call it a day. The price is lower, the setup is straightforward, and you probably already have a 9-volt battery lying around.

Now flip the script to a factory line that never quits. In places where precision counts and the environment is gnarly, skipping the brushless design can cost a fortune later. It all boils down to picking the right tool for the job, and brushless units shine where control and toughness go hand-in-hand.

Sit down first and figure out how long the thing will run, how tightly it has to steer, and how much elbow grease you’re willing to spend on upkeep. Those three questions usually point you toward the motor that makes sense.

The Future of Motors Looks Smarter, Smaller, and Sharper

Robotics is ramping up fast, and engineers want motors that pull off big tricks without hogging space-or batteries.

Brushless designs are already stepping up to the plate. Newer models hide coils and magnets so compactly that even 3D-printed shells can swallow them whole. On top of that, they now slip in temperature sensors and real-time feedback loops, and some can even chat with a controller over Bluetooth.

In tiny medical drones or the little robots that peek inside bridges, every square inch counts. Designers are cramming sensors, processors, and, yes, motors that talk back right into packages you could nearly hide in a pocket. Real-time feedback is becoming the norm instead of a wish list.

Hobbyists used to watch those fancy motors through a shop window, but that window is cracking wide open. Prices have inched down, maker faires are buzzing, and online code bundles pop up every weekend.

An eager high schooler can now grab near-industrial gear and still keep the rent money. Quality and thrift no longer do battle; they high-five.

When more people can play, the whole robotics game board shifts. Fresh voices, wild ideas, and unexpected projects start surfacing almost overnight. The discipline opens up and hands off a chunk of ownership to anyone willing to tinker.

My Opinion

Take a journal page and trace the journey from noisy brushed motors to quiet brushless motors. We’ve cross-sectioned a few, tagged along as they powered surgical arms, and felt firsthand how they redefine motion.

Brushless setups are not merely polished brushed motors; they belong to a new engine family.

These engines think on the fly, tweak their output, and keep working when the deadline looms. Whether you are sketching a weekend project or chewing through a tech article, the difference shows up loud and clear.

All those buzzing, rolling, and flying robots you see in factories, farms, or even your favorite delivery app rely on a tiny motor. That little part never seems to mess up. Whatever order the computer sends, the motor makes it happen. Every single time.

Leave a Reply

View Comments