Anyone who has ever contemplated assembling a robot, yet hesitated at the sheer complexity, is in good company. The initial intimidation is almost a rite of passage.

Walk through any generic robotics forum, and the barrage of acronyms, datasheets, and component catalogues can feel more like a crossword puzzle than a hands-on project.

To cut through that fog, I’ll guide you from the basics onward, almost as though a patient lab mate were pointing things out over coffee.

Most of the discussion will center on Pololu gear, pieces that, admittedly, carry a name that sounds slightly extraterrestrial when you first encounter it.

Veteran builders keep returning to it precisely because the brand refuses to dress up first principles in flashy marketing chatter. The motors move, the sensors report, and neither operation requires an honorary doctorate to decode.

Key Takeaways

- Pololu components work right out of the box, and their manuals explain what each wire does, so beginners stand a fighting chance.

- Grab a motor, a driver, a sensor, and a chassis, and you’ll be nudging a real robot across the floor before the weekend is over.

- When wiring and code snap together out of the box, the whole project feels less like a slog and more like fun.

- Experimenting is messy, and failure can sting, yet Pololu pieces shrug it off and ask for another try. You keep tinkering until things move, squeak, or blink, then celebrate if only for a second.

- Skills never plateau, and neither do Pololu parts. You stack, swap, or tweak them easily as your ideas grow louder than your pocketbook.

The Starting Point for Most Makers

A bare workbench, a lost smile, and only a small motor to your name-not name-not Hollywood but a classic maker moment. Almost everyone hits the same tiny, hopeful start.

One simple decision- the urge to build something that moves forward- turns a desk into a launchpad. That spark pulls you straight into the messy, rewarding universe of robotics. Pololu is the sturdy sidewalk that crosses that busy road.

Beginners often scribble lofty plans for line-following cars or curtain-sneaking sentinels. Those sketches look sweet until the parts drawer runs dry or the wiring charts become hieroglyphs. Pololu shows up right when eyeballs start to glaze.

Clear guides, honest specs, relay pins that speak Arduino without translator- that’sts the quick win almost no one else manages. The sheets read like a patient buddy leaning over your shoulder, not a cranky lecturer. Pin a piece down, update a firmware line, and the test motors cheer. No magic, just calm, steady logic.

A ruined breadboard or a rattled servo becomes tragic. You shrug, replace the piece, and keep building, because the parts play fair and ask nothing back. Pololu earns trust the simple way- because it works.

What Pololu Really Sells (Hint: It’s Not Just Parts)

At first glance, Pololu sells parts. Motors, controllers, sensors, and wheels.

But look a little closer and you discover something different. The company offers a back door to robotics that won’t force you to drain a grant budget, a trove of documents written in plain English, and hardware that forgives rookie mistakes.

So let me walk through the shelves without drowning you in jargon.

Start with the motors. Subjective toy-store chatter often calls them the heartbeat of a build, and the phrase sticks. Pololu offers compact, gearhead models that slide comfortably into the footprint of a shoebox prototype. The extra gearing slows the shaft while cranking up the torque, so a freshman bot can claw up an algebra-text ramp or nudge a stray pencil.

A typical rover chassis houses a small PCB labelled motor driver. The board translates pulses from a microcontroller into the precise current that spins the wheels. When an Arduino or a Raspberry Pi serves as the robot’s nervous system, the driver mimics a muscle signal processor, telling each motor exactly when to twitch and how quickly. Without it, commands in C or Python would never leave the desk.

Pololu sensors, on the other hand, grant the machine its eyesight. A line follower watches the tape trail, while an ultrasonic pair dodges the study walls. The same manufacturer bundles clear wiring diagrams and minimal test sketches, so exploration earns a yes long before coding fluency arrives.

Even happier to the beginner are the components inherentoilearningcfromor mistakes. A reversed power lead or a forgotten resistor rarely smokes the device; more often, it simply sits quietly while the user learns the lesson. That margin for error becomes invaluable during late-night, solder-splattered breadboard sessions.

Getting Sensors to Do the Thinking

Staring ahead, a robot depends on sensors for vision. A line follower behaves like a set of quick eyes that steer the bot along black tape; a laser rangefinder acts as windshield glass that keeps it from smacking a wall. Pololu sells many of these tiny panels, and their user guides require little more than a breadboard photo and three straight lines of text. Plug, telog- the whole sequence flows quickly.

Sensors also tolerate rookie mistakes with surprising grace. If you swap a red wire for black or leave out a resistor, the circuit often sighs and sits still rather than frying instantly. That single quality turns late-night experiments into lessons rather than disasters.

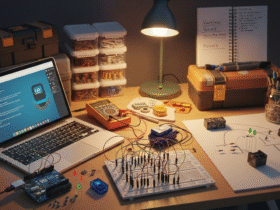

Picking Your First Setup Without Overwhelm

Picture the scene: you open a parts warehouse online, tap the search bar, and are instantly flooded by thousands of listings. The screen is so busy it almost hums, and suddenly the project feels bigger than you.

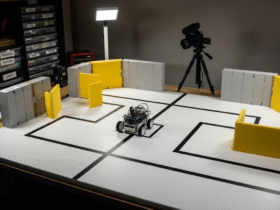

To cut through that noise, veterans often advise starting with a single, cohesive base rather than hunting for the cheapest sensors or loose motors. A pre-assembled chassis eliminates the guesswork that trips up first-timers. Pololu carries several options in that category, yet the 25D motor paired with a straightforward acrylic frame has proven reliable for generations of learners.

Hold the bare chassis in your hands, slide the motors into their slots, and something unexpected clicks; the build shifts from idea to tangible object in seconds. You instantly spot where the battery will park, and the driver board falls neatly into position on top. That gratifying moment of alignment is far less likely to happen when you scatter your order across half a dozen vendors, fumbling to match incompatible screws and connectors.

Wiring It Together and Making It Move

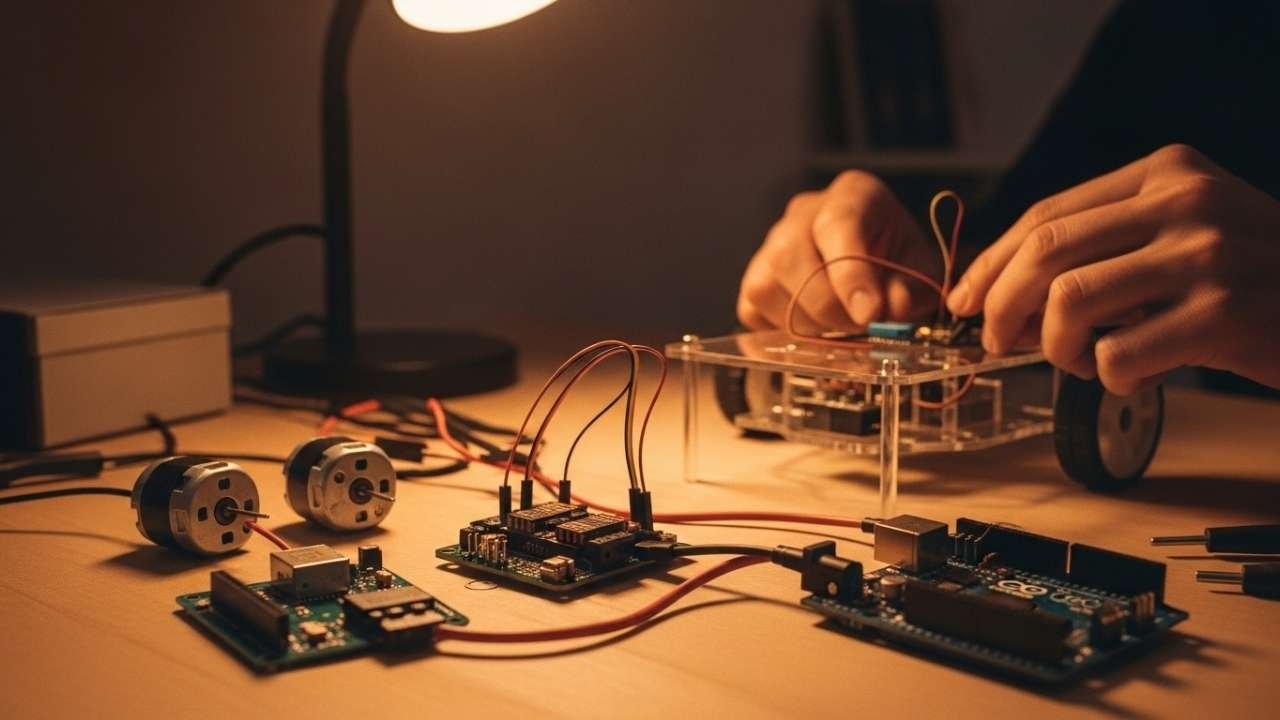

Everyone bumps into the real work sooner or later. You spread out the microcontroller, the battery pack, the driver board, and the motors on the table and suddenly wonder why they won’t just click together.

Don’t panic, though. Step by step is all that matters, and you’ve already done the hardest part by sitting down to try.

Power comes first. Check that your battery voltage sits within the sweet spot listed on the Pololu product page and forget the guesswork.

After that, hook up the motor driver to the microcontroller. Pololu tends to label itpins- IN1N1, IN2, VCCGND- everything smells like coding puzzles at first, but soon feels like tying shoelaces.

Push the code and watch the wheels twitch, and for one electricsecond you’ree a wizard. The magic isn’t perfect yet, still, it rolled, and you were the one who made it roll.

Adding Personality with Code and Creativity

Once your little rover rolls straight without wobbling, boredom can sneak in. You might suddenly picture it trailing a black line or dodging the family cat.That’ss exactly where sensors earn their keYou’lloull bang out snippets like if the eye sees black, twist ,left or if the wall looms within 10 centimeters, hit the brakes.

Each tweak makes the bot feel a little less like scrap parts and a lot more like your buddy. Not in a Hollywood, spark-plug thunderstorm way, just a fun, hands-on vibe. Move the sensor a hair, fiddle with the delay, and the personality shifts again, mistakes included. Reliable Pololu gear stays forgiving through all that trial-and-error cycle.

Real-Life Examples That Aren’t Just for Show

A 10-year-old once wired a line-follower that blitzed a classroom track in less than a minute and cheered like a pro. Another crew built battle bots packed with armor plates and nerve-wracking spinners, yells echoing down the hall. One quiet student even made a maze solver that notes its steps in memory and tries a different route each time.

Whay counts is not how fancy the finished robot loo,kit’sts the small lessons packed into every single step. You sketch out a layout, bench-test a motor, chase down a glitch when the sensors buzz, and each hassle slips in a bit of hands-on engineering know-how, label-free.

Growing Beyond the Basics

Soyou’veve finished that first little b,ot and now the upgrade itch has hit you hard. Pololu is waiting right there with wider wheels, beefier torque motors, and controllable drivers that never blink. Toss in slick sensors, swap the motors for speedy servos, or even grab a radio module and steer your machine from across the yard.

The build-your-own-robot journey has no finish line in sight. Each prototype teaches you tricks the next one will borrow, and the notebook gets dog-eared fast when curiosity is your guide. Every time you add a part, that old question What if I tried this keeps you on your toes.

Pololu likes to grow alongside its users. The budget-friendly boards hand you the basics, while the pro gear steps up the challenge without moving the target too far away. Progress feels rewarding instead of overwhelming.

You Don’t Have to Do It Alone

Jump online you’lloull find forums bursting with other Pololu fans posting pictures, trading hacks, and reassuring newcomers. Even the veteran tinkerers will admit that sometimes a mjust laughs and refuses to budge.

A single question in the right thread can snap you out of a two-hour slump, so dont hold back iyou’rere stuck. Robotics is already complicated; trying to figure it out in silence makes it worse.

Start small. Crank out your first little bot. Watch it nose-dive into a wall. Laugh. Glue the pieces back together, because that messy cycle is the real heart of robotics.

My Opinion

Pololu doesn’t stop at shiny parts; it hands you the first rung of a climbing wall. A student at lunch, a teacher squeezing in extra credit, or even a weekend tinkerer can plug in these bits and watch a dream move from sketch to stroll. No rocket-science IQ is required, just the right gear, a splash of patience, and a stubborn will to poke until it works. Stack Pololu on your workbench, and chances areyou’lll wind up building more than you ever thought you could.

Leave a Reply

View Comments